Mats - Watherhog Impressions

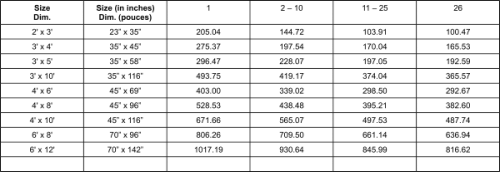

Quantity

Stock

Available on order. For delivery delay, contact us.

Shipping

infoimaginapub@gmail.com

1.819.340.0568

Description

Premium indoor logo mat. WaterHog Impressions are manufactured on a state-of-the-art digital printer with the potential of printing up to 17 primary colors. The vibrancy and high definition printing offers unequalled detail. Waterhog Impressions feature an attractive fabric “water dam” border that holds up to 1.5 gallons of water per square yard.

| SURFACE | |

| FIBER TYPE: | Solution-dyed polypropylene, outstanding light fastness |

| WEIGHT: | 24 oz. per square yard (884 grams per square meter) |

| NUB HEIGHT: | 1/4" |

| DESIGN: | Square "waffle" |

| BACKING | |

| TYPE: | 100% SBR Rubber (20% Recycled content) |

| THICKNESS: | .190" - Nubs .050" - Between Nubs |

| DUROMETER: | 60 |

| TENSIL: | 1100 |

| FEATURES | |

| 1. | Reinforced face NUBS: Face NUBS are reinforced with rubber to resist crushing, maintaining high performance and extending product life. |

| 2. | "Water Dam" border: Border is designed to hold water and dirt on mat keeping them off carpets and floors. Unique raised fabric border allows mats to hold up to 1 1/2 gallons of water per square yard. Some styles available without dam for outside use, so water can drain easily. |

| 3. | Raised NUB surface: Removes and traps dirt and moisture and holds it on mat below shoe level so it is not tracked in. |

| 4. | TriGrip backing: Gripping action minimizes movement on surfaces. |

| 5. | Rubber backing: Lays flat, won’t crack or curl like vinyl mats. |

| 6. | Indoor/Outdoor: Durable polypropylene face suitable for indoor or outdoor use. Polypropylene fiber system dries quickly preventing fading and rotting. |

| 8. | Easy to clean: Just vacuum or hose off and hang to dry. |

| 9. | Colorfast: High degree of light fastness |

| 10. | Not adversely effected by salt or ice melt. |

| 11. | Should not be used in areas exposed to animal fats (kitchens) |

| 12. | Passes Flammability Standard DOC-FF-1-70 |

| 13. | ASTM C 1028-29 Static Coefficient of Friction. Dry .70 |

| 14. | Anti-static: Waterhog Inlay mats have a maximum average voltage of 1.6 KV as measured by the AATCC 134 Electrostatic Propensity Test and meets IBM’s resistance (NFPA99). Waterhog mats are safe for use in computer rooms and around electronic equipment. |

CLEANING INSTRUCTIONS

| 1. Vacuum Daily |

| When possible, Waterhog mats should be vacuumed on a daily basis. During periods of inclement weather, use of a wet/dry vacuum may provide a more effective method of daily maintenance. |

| 2. Routine Maintenance |

| Spots and non-permanent stains should be removed as needed using a safe non-organic solvent based cleaner. In the event a solvent based spotter is needed, caution should be taken to rinse the excess solvent thoroughly before returning the mat to service. Failure to rinse the solvent can result in damage to the rubber backing of the mat. Periodically, as needed, Waterhog mats should be cleaned using a more vigorous method such as a pressure washer or water hose. Following the use of this method, the mats should be placed in a position to allow them to drain. This draining will occur rapidly and the mats will be ready to put back into service in a short time. |

| 3. Deep Cleaning |

| Waterhog mats may be cleaned by any routine method used for carpeted floors. This includes wet extraction as well as low moisture extraction methods. Chemicals used for cleaning should be as solvent-free as possible and following a wet cleaning, care should be taken to rinse the mat as thoroughly as possible. If a wet system is used, the mats should be placed in a position to drain as much as possible before returning to service. |

| 4. Floor Preparation |

| Prior to the mat being put back into service, Logo Mats recommends that the floor where the mat will be placed be cleaned to remove dust and dirt. This will allow the mat to grip the floor more effectively reducing mat movement with traffic. |

Picture

Similar

$1,000.00

$

1,000

00

CAD

CAD

$

999

99

CAD

CAD

$

999

99

CAD

CAD

Save

$0

Save

$0

Save

$0

Save

$0

Save

$0

Save

$0

Save

$0

Save

$0

Save

$0

Save

$0

Save

$0

Save

$0

Save

$0

Save

$0

Save

$0

Save

$0

Save

$0